UHMWPE Lined Steel Pipe

UHMWPE lined steel pipe

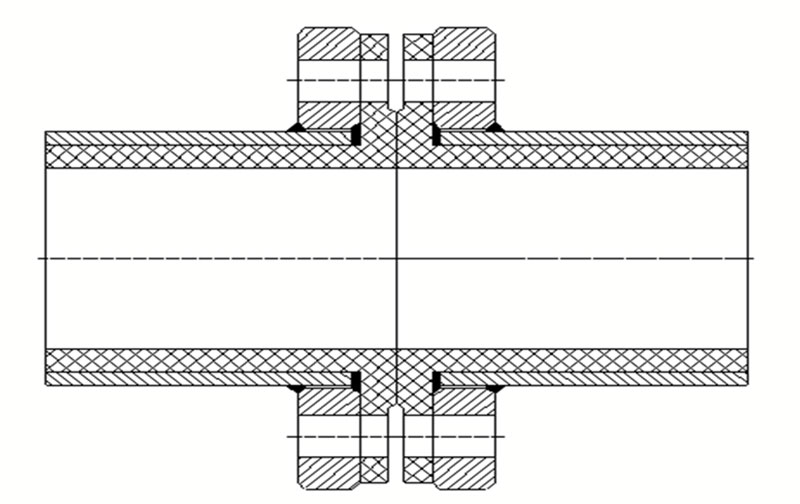

also named high wear resistant PE-steel composite pipe, it is combined by carbon steel pipeline and UHMWPE pipeline through special technical method, and the diameter of the composite pipe is available from DN200~DN1200.

Attributes of UHMWPE Pipe

Steel Pipe For Sale!

UHMWPE lined steel pipe

also named high wear resistant PE-steel composite pipe, it is combined by carbon steel pipeline and UHMWPE pipeline through special technical method, and the diameter of the composite pipe is available from DN200~DN1200.

Benefits of UHMWPE lined Steel Pipe:

1. Bear high pressure, the UHMWPE -steel composite pipe can bear pressure from 5~8 Mpa.

2. High wear-resistant ability, among all the plastic materials, UHMWPE is the best one for wear-resistant ability, cause its average molecular weight is above 1.5million, while the HDPE material is only 0.3~0.5 million, and by test, the UHMWPE pipeline is 4 times wear-resistant than HDPE pipeline. By lining the UHMWPE pipeline inside the steel pipe, which can increase 6 times wear-resistant ability.

3. Low water-resistant, low friction coefficient, nonscaling, save fuel engine cost, because the roughness of the UHMWPE pipeline is only 0.00022, while HDPE is 0.01 and steel is 0.1. By lining the UHMWPE Pipeline inside the steel pipeline, the whole pipeline will save at least 20% fuel engine cost.

4. Anti-corrosion, the inner UHMWPE pipe with very stable chemical property, it is anti-corrosion from a strong acid, alkali, salt, water, sewage, soil corrosion, which increase the using life of the whole pipeline perfectly.

Applications of UHMWPE lined Steel pipe:

| Specification(mm) | UHMWPE Wall thickness(mm) | Steel pipe wall thickness(mm) | Work Pressure MPa |

| 200 | 10.0 | 6.0 | 6.0 |

| 250 | 10.0 | 6.0 | 5.0 |

| 300 | 10.0 | 6.0 | 5.0 |

| 350 | 15.0 | 6.0 | 4.0 |

| 400 | 15.0 | 8.0 | 4.0 |

| 450 | 15.0 | 8.0 | 3.5 |

| 500 | 15.0 | 8.0 | 3.0 |

| 550 | 15.0 | 8.0 | 3.0 |

| 600 | 15.0 | 10.0 | 3.0 |

| 650 | 20.0 | 10.0 | 3.0 |

| 700 | 20.0 | 10.0 | 3.0 |

| 750 | 20.0 | 10.0 | 2.5 |

| 800 | 20.0 | 10.0 | 2.5 |

| 850 | 20.0 | 12.0 | 3.0 |

| 900 | 20.0 | 12.0 | 2.5 |

| 1000 | 25.0 | 12.0 | 2.5 |

| 1200 | 25.0 | 12.0 | 2.0 |

Feature about Steel Pipe

high wear resistance:

UHMW items distinct molecular framework, to make sure that it has a very high ability to stand up to gliding. Put on resistance is higher than the basic alloy steel 6.6 times, stainless steel 27.3 times. is phenolic material 17.9 times, nylon six 6 times, polyethylene 4 times the annual wear price of 0. 58, the life span of the pipeline is considerably enhanced.

exceptionally high influence resistance, in the existing engineering plastics, the effect toughness of this item is the greatest, many products in extreme or repeated explosions of the impact of cracks, breakage, crushing or surface tension tiredness. This product according to the GB1843 standard, continues the cantilever light beam effect experiment to accomplish no damage.

outstanding chemical security:

this item can stand up to strong chemical erosion, along with certain acids at raised temperature levels there is slight corrosion, in various other lye, the acid remedy is not rust. It can be made use of in focused hydrochloric acid with a focus of less than 80%, the efficiency is relatively stable in nitric acid with a concentration of less than 75% as well as a focus of less than 20%.

good self-lubricating, due to the fact that this item contains a wax-like product, and its own lubrication is good. The coefficient of friction (196n,2 hours) is only 0.219 mn/m (GB3960). The self-sliding performance transcends to oil-lubricated steel or brass. Especially in the setting, dirt, sand as well as lots of places, the product of its very own dry lubrication efficiency much more fully presented. Not just can work out openly, as well as protect the related work surface does not use or pull injury.

safe to the organic:

ultrahigh molecular weight Polyethylene Engineering Plastics (UHMW-- PE) pipeline to adjust to water quality liquids, solid fragments, powders, slurry, and so on, the standard metal pipe difficult to fulfill the requirements of ultra-high molecular weight polyethylene (UHMW-- PE) pipeline can be changed by extremely high corrosion resistance, high wear resistance, Self-lubricating absorption shock as well as other extensive properties, in different industries have a large range of applications in strong bits, powder, slurry, gas transport, has a special benefit.

the unique low-temperature resistance:

this product is outstanding low-temperature resistance, its impact resistance, wear resistance in Minus 269 levels Celsius fundamental unmodified. It is the only sort of design plastics which can work at a temperature level near to absolute 0 levels currently. At the same time, the temperature of the product is vast, can be long-lasting in the 269 ℃ to 80 ℃ of job.

the surface is not adhered to, this product as a result of the small rubbing coefficient and the infinite, it has a good surface attachment. The existing materials typically in the ph value of greater than 9 of the medium are scaling, this product is not scaling, the attributes of fire power plant for the discharge of fly ash system has terrific significance. In crude oil, mud and various other transportation pipelines are likewise really suitable.

The best resistance to environmental tension splitting:

resistance to ecological anxiety cracking > 4000h, flexible modulus is 1.5 times greater than PE100, anti-fatigue strength of 500,000 times.

other characteristics, the product additionally has absorption, noise absorption, anti-static, the neutron has securing capability, do not soak up water, lightweight. Easy machining, coloring and also other superior attributes.

we are steel pipe manufacturer, we have many cases all over the world,click here for details!

Key Application of UHMWPE Pipe